As technological advancements continue at a rapid pace, there's growing anticipation about the potential integration of Artificial Intelligence (AI) and automation across various industries, and the SMT (Surface Mount Technology) sector is no exception. Especially in the realm of manufacturing, the prospective merger of AI and automation could redefine the future of the SMT landscape. This article seeks to explore how AI might optimize component placement, enable real-time fault detection, and facilitate predictive maintenance, and how these advancements could shape our production methodologies in the years to come.

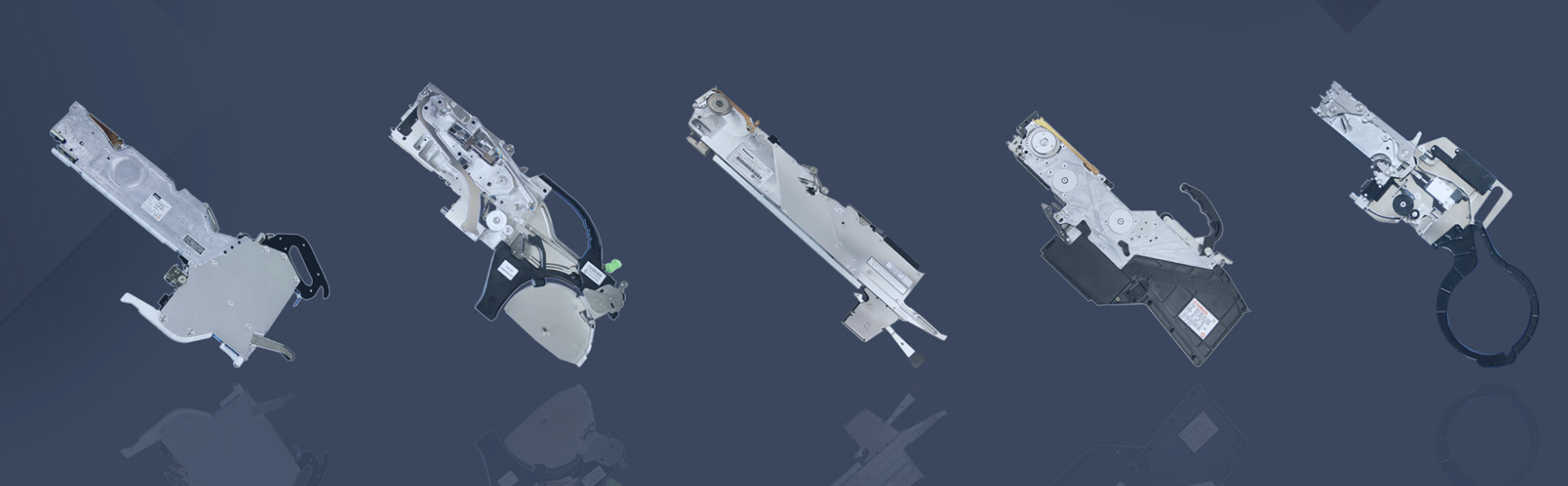

1.AI-Powered Component Placement

Traditionally, component placement was a meticulous process, requiring both precision and speed. Now, AI algorithms, through their ability to analyze vast amounts of data, are optimizing this process. Advanced cameras, paired with AI, can identify the correct orientation of components faster than ever before, ensuring efficient and accurate placement.

2. Real-time Fault Detection

Detecting errors during the SMT process is crucial for quality control. With AI, it's possible to spot inconsistencies or faults in real-time. AI-driven systems continuously analyze data from the production line, detecting anomalies and potentially preventing costly manufacturing errors. This not only reduces waste but also ensures that products meet the highest standards of quality.

3. Predictive Maintenance

Maintenance in the SMT world has been mostly reactive. However, with AI's predictive analytics capabilities, this is changing. AI systems can now analyze patterns and trends from machinery data, predicting when a part might fail or when a machine may need maintenance. This proactive approach reduces downtime, ensuring continuous production and saving on unforeseen repair costs.

4. The Harmony of AI and Automation

The integration of AI with automation in the SMT industry offers limitless possibilities. Automated robots, driven by AI insights, can now perform complex tasks with greater efficiency. The data that AI processes from these automated systems also helps in refining operational processes, further enhancing productivity.

In conclusion, the fusion of AI and automation is setting a new course for the SMT industry. As these technologies continue to mature and become more integrated into daily operations, they promise to bring about efficiency, quality, and innovation like never before. For businesses in the SMT sector, embracing these changes is not just a pathway to success; it's essential for survival.

www.rhsmt.com

info@rhsmt.com

Post time: Nov-01-2023