RHSMT: Your One-Stop Shop for Wholesale SMT Placement Machines

Looking for a reliable Surface Mount Technology (SMT) placement machine supplier? Look no further than RHSMT. We are experts in the field and can provide you with any type of SMT placement machine you need. Additionally, we offer a wide range of products and accessories to meet your needs. Contact us today to learn more about our products and services! We are confident that you'll be satisfied with our quality and service. With years of experience in the industry, we guarantee to provide top-notch Surface Mount Technology products that will meet all your requirements. Let RHSMT help you find the perfect SMT placement machine today!

Ruihua Electronics Co., Ltd, where we are dedicated sellers of Surface Mount Technology (SMT). As one of the leading companies in China, we offer a wide range of SMT placement machines and accessories that are available at wholesale prices. All our products are guaranteed to be of high quality and affordably priced.

We understand that finding the right Surface Mount Technology machine can be tricky. That is why we have a team of experienced professionals on hand to help you find the perfect SMT placement machine for your needs. From consultation to installation, our technicians can help you every step of the way.

At RHSMT, we provide our customers with the best Surface Mount Technology products that meet their requirements. If you are looking for SMT machines from Panasonic, Fuji, Juki, Yamaha, Samsung, Assembleon, DEK, Siemens, Hitachi, SMT Equipment like pick and place machines, ESD Products, Auto Inserter (AI) Spare parts, etc. Some of the products that we carry are:

The Yamaha YSM20 Placement is a versatile and high-efficiency pick and place machine that can support components ranging from 03015 to 45 x 45 mm in size. It is also the world's fastest in its class.

With its "1 head solution", the Yamaha YSM20 Placement aims to provide users with an ideal mounter that offers both high speed and versatility! With this machine's wide support capability, the "Limitless EXpansion" concept has become reality. Numerous functions enable it to produce high-quality mounting results as standard. Feeders and supply devices offer plenty of freedom for users. Get this pick and place, chip mounter and placements SMT machine at the best rate from us.

The printer, placements, and inspection processes are integrated to result in increased productivity and quality.

Configurable modules enable flexible line configuration. Plug-and-play functions allow for head location flexibility.

System software provides complete line, floor, and factory control: Monitoring line operations provides production plan support.

- The Panasonic NPM-D3 can handle both single and multiple dual-lane boards, making it versatile and scalable.

- With a small footprint and dual-sided operation, the NPM-D3 maximizes factory floor space utilization.

- The machine includes an industry first: a field-scalable multi-recognition camera that combines alignment, thickness, and 3D coplanarity into one quick step—saving you time while improving your process overall!

The NEW NXT Ill is a productive machine that can do many tasks. It is built to be fast, with a faster XY robot, tape feeders, and a new H24 head that achieves 35,000 chips per hour. The NXT III supports the smallest parts being used in mass production while still being accurate.

The newly developed XY robot, along with faster tape feeders and a "flying vision" parts camera, provides increased placement ability for all part sizes and types. The new H24G high-speed head achieves 37,500 cph (chips per hour) (Productivity priority mode) per module, 44% faster than the NXT II.

The NXT III can handle 0201 mm Part Support, +/- 0.025 mm Placing Accuracy, and the smallest parts currently being used in mass production (0402 mm, 01005"). The next-generation components are also heading to the market - 0201 mm parts. The GUI of the original NXT was widely praised for using intuitive and easy-to-understand pictograms instead of language-based instructions.

The touchscreen panel interface makes operation now easier than ever before by reducing the number of buttons pushes required and making selecting commands easier. This also improves quality by eliminating the potential for human error. In fact, many of the main units from the NXT II, such as placing heads, nozzle stations, feeders, tray units, and feeder pallet exchange units, can be used on the NXT III without any modifications at all!

Fuji has achieved an accuracy of +/- 0.025 mm for small chip parts (3sigma, Cpk≥1.00) by improving machine rigidity and further refining its independent servo control and visual recognition technology.

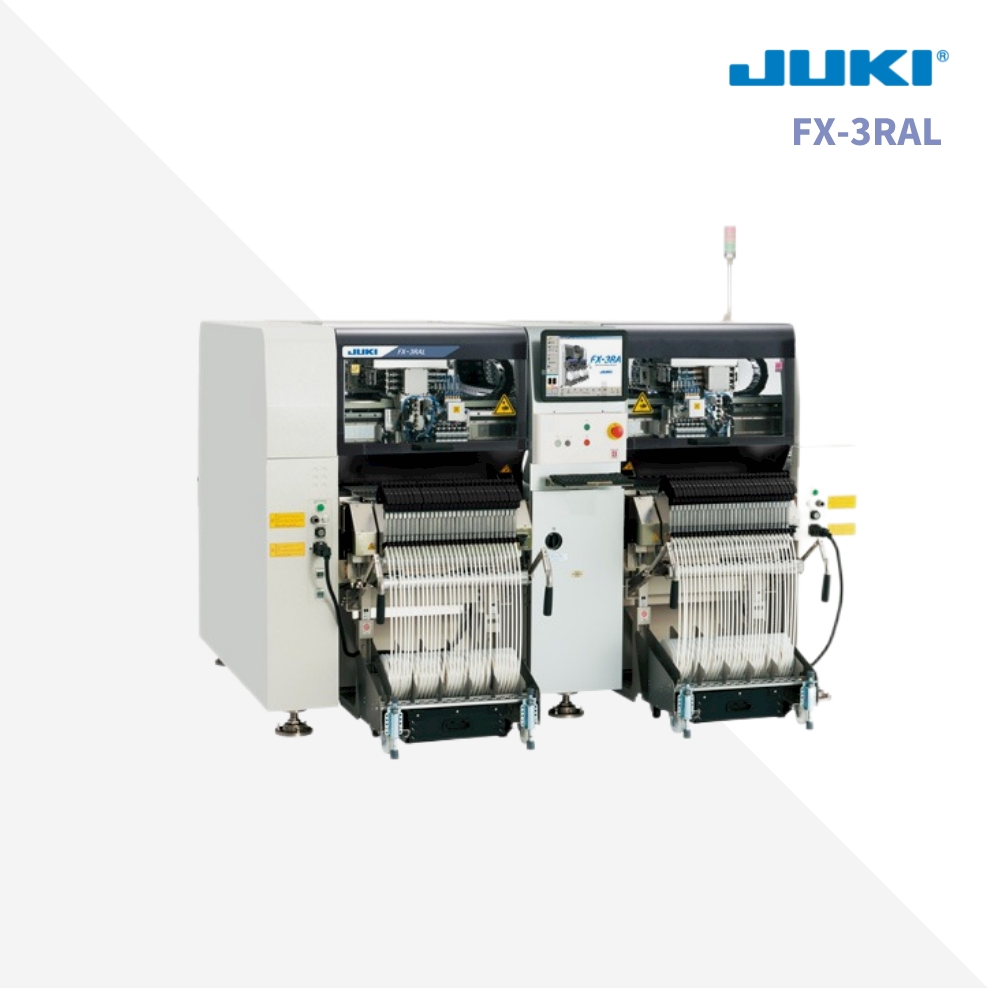

Our FX-3 high-volume production technology is the latest modular assembly line manufacturing advancement. With an interchangeable electronic and mechanical feeder solution, along with a new 22" × 24" board size, the FX-3 offers maximum flexibility, reliability, and ease of use for both high-speed and high-mix environments.

The IPC9850 (chip) can handle 60,000CPH*. With 8mm Tape feeders, it has a max. 120 component inputs that range from (01005) 0402 to 33.5mm squares. Plus, there are four multi-nozzle laser heads(24 total nozzles).

With its versatile design, the DEK HORIZON 03IX can suit your production needs - whether you require a high volume or need to handle small batches flexibly. Whatever setup you need, the DEK Horizon will give you what We specialize in supplying used printers that are still in good condition and have low working hours. All machines receive surface treatment before leaving our warehouse.

The Juki Model KE-2070L PCB pick and place machine is ideal for assembly work. This particular unit, s/n 270-D1638, has an hour meter reading of 19037 and is in working condition. Additionally, it comes with a Head - 6 Shafts (JVS7) unit installed. It requires 3-phase power at 460V and dimensions 72inL by 60inW by 66inH. The weight of the device is approximately 3400 lbs.

Surface Mount Technology (SMT) is the process of mounting electronic components onto a printed circuit board. It has become the industry standard for manufacturing electronics, and RHSMT is one of the leading sellers of SMT equipment worldwide. This article highlights some of our most popular products: Juki high-speed modular mounters, DEK Horizon 03IX screen printers, Yamaha 3D hybrid optical inspection systems, and Juki PCB pick and place machines. All machines receive surface treatment before leaving our warehouse. Furthermore, we supply Auto Inserter spare parts for various models of AI machines. Our company prides itself on providing high-quality products that meet the needs of our customers. If you are interested in any of the items mentioned in this article or require more information, please do not hesitate to contact us.

Post time: Dec-10-2022